Approved by the ministry of Foreign Economic Relations and Trade of the P.R.C. and the department of Commerce of Hunan Province, our company is a large comprehensive foreign trade enterprise with an i...

- YRS

Approved by the ministry of Foreign Economic Relations and Trade of the P.R.C. and the department of Commerce of Hunan Province, our company is a large comprehensive foreign trade enterprise with an i...

| Min. Order / Reference FOB Price | |

|---|---|

| 100 Piece | US $9.00/ Piece |

| Local Area: | Changsha, Hunan, China |

|---|---|

| R&D Capacity: | OEM, ODM, Other |

| Payment Terms: | LC, T/T, D/P, Paypal, Western Union |

| Brand: | OEM |

|---|---|

| Place of Origin: | Zhejiang, China |

| Brand Name: | OEM |

| Model Number: | OEM |

Stainless steel and plastic fuel 6804 bimetal strip fork stem bearing hardware accessories bushing

Product Description

DU Bushing Technical data:

Material: 1. Steel + Bronze powder + PTFE + Pb + Polymer 2. Steel + Bronze powder + PTFE + Polymer - Normally Used 3. Bronze + Bronze powder + PTFE + Polymer 4. Stainless steel + Bronze powder + PTFE + Polymer 5. Stainless steel + PTFE + Polymer 6. Carbon steel + Sintered bronze powder + PTFE + MoS2 |

| Structure | PTFE with lead/Cu/Fibre : 0.01-0.03mm |

| Porous bronze : 0.2-0.3mm | |

| Steel backing : 0.7-2.3mm | |

Tin-plating 0.005mm or copper plating 0.008mm |

| Type | Load capacity(N/mm2) | PV limit(N/mm2*m/s) | Speed limit (in oil) | Temp.limit | μ Frictio Coef. | Themal conductivity | Linear expansion | |||

| Static | Dynamic | Oscillating | Oil | Dry | (m/s) | (℃) | (W/MK) | |||

| SF-1X | 250 | 140 | 60 | 50 | 3.6 | 5.0 | -195~270 | 0.04~0.20 | 13 | 11*10(-6)/k |

| SF-1T | 250 | 140 | 60 | 60 | 4.3 | 10 | -195~260 | 0.03~0.18 | 13 | 11*10(-6)/k |

| SF-1P | 250 | 140 | 60 | 50 | 1.8 | 2.5 | -195~270 | 0.04~0.20 | 13 | 11*10(-6)/k |

| SF-1W | 250 | 140 | 60 | 50 | 3.6 | 5.0 | -195~300 | 0.04~0.20 | 13 | 11*10(-6)/k |

| SF-1B | 250 | 140 | 60 | 60 | 4.3 | 5.0 | -195~270 | 0.04~0.18 | 18 | 21*10(-6)/k |

| SF-1D | 250 | 140 | 60 | 50 | 3.8 | 3.0 | -195~270 | 0.04~0.18 | 16 | 15*10(-6)/k |

| SF-1S | 250 | 140 | 60 | 50 | 3.6 | 4.5 | -195~270 | 0.04~0.20 | 16 | 15*10(-6)/k |

| SP-1SS | 250 | 140 | 60 | 40 | 3.0 | 2.5 | -195~270 | 0.04~0.25 | 13 | 15*10(-6)/k |

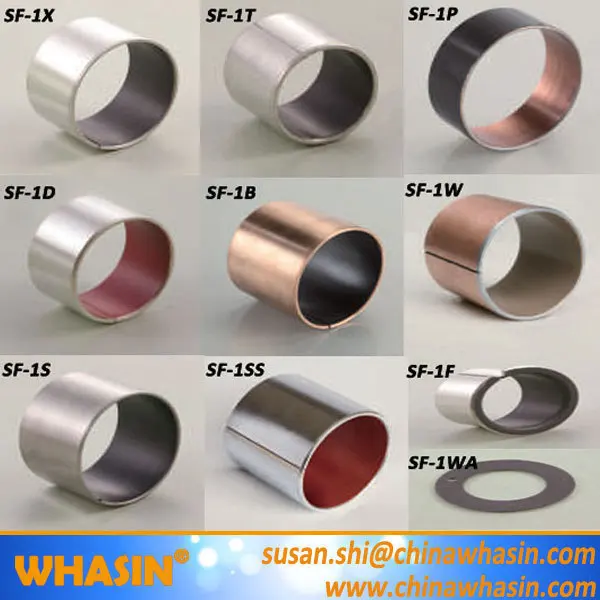

DU Bushing Photo:

DX Bushing Technical data:

Material: 1. Steel + Bronze powder + POM + Pb 2. Steel + Bronze powder + POM - Normally Used |

| Structure | POM with/without lead : 0.3-0.5mm |

| Porous bronze : 0.2-0.3mm | |

| Steel backing : 0.4-2.2mm | |

| Tin-plating 0.005mm or copper plating 0.008mm |

| Physical and mechannical performance | Load capacity | Static load | 250N/mm2 |

| Dymamic load | 140N/mm2 | ||

| Oscillating | 60N/mm2 | ||

| Speed limit(in oil) | 2.5m/s | ||

| PV value limit | Oil lubrication | 22N/mm2.m/s | |

| Dry lubrication | 2.8N/mm2.m/s | ||

| Friction coef u | 0.05~0.25 | ||

| Working temperature | -40℃~+130℃ | ||

| Themal conductivity | 13W/mk | ||

| Coefficient of linear expansion | 11x10(-6)/k |

DX Bushing Photo:

Bimetal Bushing Technical data:

Material: 1. Steel + Bronze alloy (CuPb10Sn10) + PTFE 2. Steel + Bronze alloy (CuPb10Sn10) 3. Steel + Bronze alloy (CuSn4Pb24) 4. Steel + Bronze alloy (CuPb24Sn) 5. Steel + Alloy stage (AlSn20Cu) 6. Steel + Bronze alloy (CuPb30) |

| mechannical performance | Load capacity | Static load | 150N/mm2 |

| Max.Working temperature | Grease Lubrication | 150℃ | |

| Oil Lubrication | 250℃ | ||

| PV value limit | Oil lubrication | 10N/mm2.m/s | |

| Dry lubrication | 2.8N/mm2.m/s | ||

| Linear Velocity | Dry Friction | 0.4m/s | |

| Grease Lubrication | 2.5m/s | ||

| Mating Axis | Hardness | ≥53 HRC | |

| Roughness | Ra-0.32~0.63 | ||

| Anti-tensile Strength | 185 N/mm2 | ||

| Alloy Hardness | HB 60~90 | ||

| Friction coefficient | 0.05~0.22 | ||

| Themal conductivity | 47W/mk | ||

| Heat-expansion Coefficient | 18x10(-6)/k |

BimetalBushing Photo:

Graphite Bronze Bushing Technical data:

Material: 1. CuZn25Al6Fe3Mn3 + Graphite 2. ZCuAl9Fe4Ni4Mn2 + Graphite 3. ZCuSn5AlPb5Zn5 + Graphite 4. ZCuSn10Zn2 + Graphite 5. HT250# Cast Iron + Graphite 6. CuZn25Al6Fe3Mn3 (High-stress Brass) |

| Physical and mechanical Performance | Density | 8.2 g/cm3 | |

| Linear Expansion Coefficient | 1.6-2.0 10(-5)/℃ | ||

| Heat-conducting Coefficient | 38-55W(/m.k) | ||

| Tensile Strength | ≥755 N/mm2 | ||

| Anti-compact Tenacity | ≥400-500 KJ/m2 | ||

| Hardness | ≥ 210 HB | ||

| Flexibility Coefficient | 100-140 KN/mm2 | ||

| Tensility | ≥ 12% | ||

| Friction | Oil Lubrication | 0.03u | |

| Dry Lubrication | 0.16u | ||

| Working Temperature Limits | -40℃ ~+300℃ | ||

| Max Load Pressure | 100N/mm2 | ||

| Max Linear Velocity | 0.50 m/s | ||

| Max PV Value | 1.65N/mm2.m/s |

Graphite Bronze Bushing Photo:

Wrapped Bronze Bushing Technical data:

Material: 1. CuSn8P / CuSn8 2. CuSn6.5P / CuSn6.5 3. CuZn31Si |

| Physical and mechanical Performance | Mating Axis | Hardness | ≥50 HRC |

| Roughness | 0.4~1.0 | ||

| Max Load Pressure | 100 N/mm2 | ||

| Max Linear Velocity | 2 m/s | ||

| Max PV Value | 2.8 N/mm2*m/s | ||

| Tensile Strength | 460 N/mm2 | ||

| Yield Strength | 260 N/mm2 | ||

| Hardness | 90-150 HB | ||

| Working Temperature | 150 ℃ | ||

| Friction Coef. | 0.05~0.2u | ||

| Heat Conducting Coef. | 58W/(m*k) | ||

| Heat Expansion Coef. | 18.5 (10(-6)k(-1) |

Wrapped Bronze Bushing Photo:

Sintered Bronze Bushing Powder metalurge PM Motor Fan Iron Bearing Technical data:

| material code | composion% | character | |||||||||

| Fe | C | Cu | Sn | Zn | Pb | other | Oil density g/cm3 | Oil rate % | Horizontal Break point kgf/mm2 | Hardness HB | |

| FU11 | <0.5 | 0.5~2.0 | Allo. | 5~7 | 5~7 | 2~4 | <1.5 | 6.4 | ≥18 | >15 | 20~50 |

| FU12 | <0.5 | 0.5~2.0 | Allo. | 5~7 | 5~7 | 2~4 | <1.5 | 6.8 | ≥12 | >20 | 30~60 |

| FU21 | <0.5 | 0.5~2.0 | Allo. | 8~11 | - | - | <1.0 | 6.0 | ≥25 | >15 | 25~55 |

| FU22 | <0.5 | 0.5~2.0 | Allo. | 8~11 | - | - | <1.0 | 6.4 | ≥18 | >20 | 35~65 |

| FU31 | Allo. | - | 18~22 | - | - | - | <3 | 6.0 | ≥18 | >30 | 30~60 |

| FU32 | Allo. | - | 18~22 | - | - | - | <3 | 6.4 | ≥12 | >35 | 40~70 |

| FU41 | Allo. | 0.25~0.60 | - | - | - | - | <3 | 6.0 | ≥18 | >15 | 30~60 |

| FU42 | Allo. | 0.25~0.60 | - | - | - | - | <3 | 6.4 | ≥12 | >20 | 40~70 |

| FU51 | Allo. | 0.25~0.60 | CuSn P6 70~90 | <3 | 6.4 | ≥18 | >30 | 30~60 | |||

| FU52 | Allo. | 0.25~0.60 | CuSn P6 50~70 | <3 | 6.8 | ≥12 | >25 | 40~70 | |||

| Performance index | Data |

| Maximum load capacity | 150 N/mm2 |

| Temperature range | -60~+200 ℃ |

| Maximum sliding speed | 2.5 m/s |

| Alloy material | CuSn6-6-3 |

| Maximum PV value | 2.45 N/mm2*m/s |

Sintered Bronze Bushing Powder metalurge PM Motor Fan Iron Bearing Photo:

Bushing Photo

Packaging & Shipping

Company Information

FAQ

Contact information: