Zhangjiagang HongYang Petrochemical Machinery Co., Ltd is located in Jiangsu Zhangjiagang is located by the Yangtze River, and surrounded by many international cities such as Shanghai, Nanjing and Suz...

- YRS

Zhangjiagang HongYang Petrochemical Machinery Co., Ltd is located in Jiangsu Zhangjiagang is located by the Yangtze River, and surrounded by many international cities such as Shanghai, Nanjing and Suz...

| Min. Order / Reference FOB Price | |

|---|---|

| 1 Set | US $1250000.00/ Set |

| Local Area: | Jian, Jiangxi, China |

|---|---|

| R&D Capacity: | OEM, ODM, Other |

| Payment Terms: | LC, T/T, D/P, Paypal, Western Union |

| Brand: | HongYang |

|---|---|

| Type: | Coating Production Line |

| Substrate: | Aluminum |

| Condition: | New |

Aluminum Color Coating Production Line

Aluminum Coil Color Coating Production Line

Hongyang machinery has the advance production line for coating the aluminum coil, it can be suitable for high gloss, polyester, PVDF, FEVE, mirror, stone, wooden, water paint etc.

All this coated coil can be used for Aluminum composite panel, wall cladding, facades, roofing, signboards, blind window, electrical panel, kitchen panel, food container, bottle cap, etc.

If you want to know more HonGYANG MACHINERY service , pls send us inquiry without hesitate !

Products Description

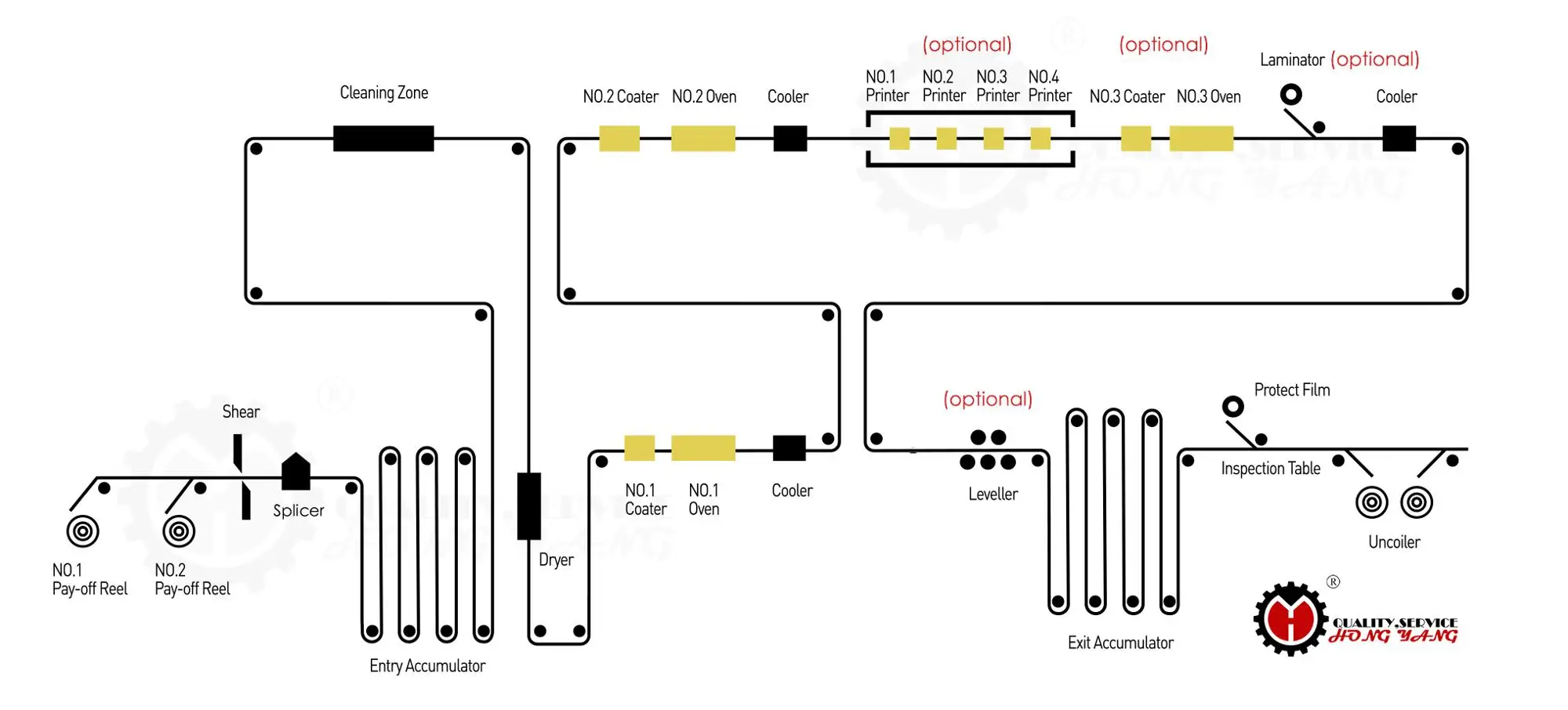

The Advanced Aluminum Color Coating Production Line

The production line is designed by Hongyang Machinery, which used to describe the application of a decorative and /or protective organic coating to metal supplied in coil form.

To design a line to meet the customer’s capacityrequirements, Hongyang requires a reference coil width andthickness, together with maximum/minimum thicknessand widths. The reference strip is the strip size mostcommonly processed.With this information our designers are able todetermine:

1. The thermal capacity of the oven and the strip contacttime in the oven and/or

2. The maximum process section line speed

The initial selection of these parameters must be suitedto the desired output. To purchase a line with excesscapacity would be over-capitalising, and one withinsufficient capacity means losing market share.

Pretreating System

No matter what the feed coil type, the strip must be pre-treated before paint is applied to obtain any acceptable level of prolonged paint adhesion and corrosion resistance.

Prior to pre-treatment the feed is cleaned to remove oil and any other surface contaminants. This is done in high pressure spray tanks with contact times of between 2 and 5 seconds. The solution is normally hot (60 -70 degC) alkali although acid based cleaners are also available. Following the cleaning tanks usually two hot (50 -60 degC) water spray tanks are used to be sure that the alkali from cleaning is not carried through to the pre-treatment stage. Between each spray tank rubber squeegees also prevent carry through of the solution from one tank to the next.

Following cleaning, the pre-treatment is applied. This is usually chromic or phosphoric acid based although chromium free systems are now available. The pre-treatment performs a dual function.

● It creates a very high bond between the paint and the base metal.

● It provides corrosion protection. Without the pre-treatment protection, any cuts,

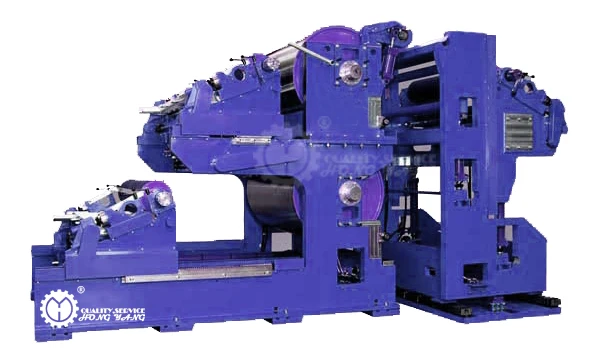

S-Type Coater System

This machine is the most popular machine used. The main advantage of this machine is that the Top Head paints the strip as the strip is supported around a large diameter Back-Up Roll. This Back-Up Roll supports the strip and keeps it very flat so the painting process can be done very accurately. This machine provides very good operator access and visibility on both the top and bottom sides of the strip.

C-Type Coater System

This machine is also a modification of the S-Type Coater Machine. It operates in a similar manner to the U-Type Coater Machine in that it is also a Color Quick Change Coater. The main difference here is that the two Back-Up Rolls are positioned vertically above each other whereas in the U-Type Coater Machine, the Back-Up Rolls are positions horizontally apart from each other.

Baking Oven System

The oven fan blade all use the SS304 stainless steel, and the whole body used 200 thick thermal insulation cotton wool, so the oven surface can't feel any extra heat.

Such kind high-performance floatation oven for drying the solvents stands out for even heating performance, and exceptionally high efficiency. To ensure a flawless finish, the strip travels contact-free through the entire furnace.

Automatic Electrical Control System

Hongyang's machine all standard use the Schneider brand low voltage components.

The Plc, HMI, all choose the Siemens brand. The Inverter choose the ABB brand.Which all world famous. It makes customer satisfy the system stability.

RTO System (Regenerative thermal oxidizer)

The solvent-containing gasses are exhausted from the oven and cleaned in an RTO with high thermal efficiency. Depending on the solvent content in the exhaust air it is possible to operate the post-combustion system and, when using a highly efficient energy recirculation system, the ovens without feeding additional energy.

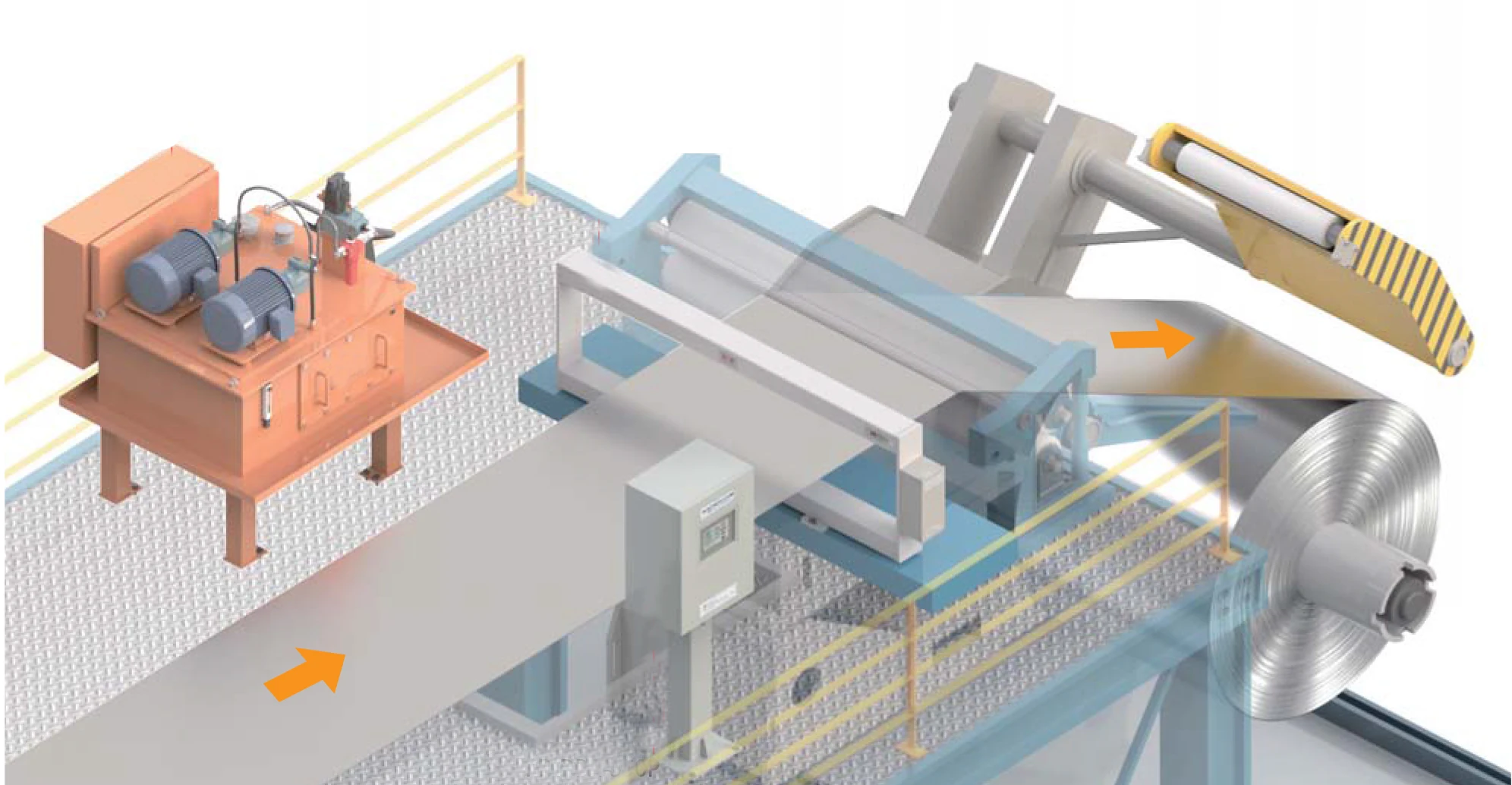

EPC Rewinding System

In order to get perfect rewinding edge for the coil roll, Hongyang cooperated with famous brand EPC &CPC system company, to make the strip automatic rectify the position of the strip, make sure strip always in the center with right tension. When in rewinding process, the EPC system can make the edge smooth, also can make staggered.

Application

● Roofing &wall cladding

● Guttering

● Fences &walls

● Whitegoods

● Roofing tiles

● Pop can

● Composite panel

● Solid aluminum

● Office furniture

● TV board

● Sports equipment

● Windows shades

● etc.

Hongyang Service

What Hongyang Machinery can do for you ?

Professional.

Professional engineers supply suitable machine according to customer requirements.

Machine Layout.

We will make the machine layout design according to your factory conditions.

Sample Project.

When you visit us we can provide a sample project for you to visit

If you want to know more HonGYANG MACHINERY service , pls send us inquiry without hesitate !

Packing & Delivery

HonGYANG MACHINERY | |

Conventional packaging: outside is wooden box. | |

Delivery. | The normal delivery period is 90 days, depending on the place order time, the specific time is about 90 to 120 days. |

Details. | We will make detail packing lists even one nut, also make very clear photo for each package. |

about Hongyang Machinery

Zhangjiagang Hongyang Petrochemical Machinery Co.,Ltd.

1 / Standardized workshop of total 10,000 square meters. 2 / The equipment will be well assembled and test before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability. 3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

Hongyang Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different product with different kinds of requirements and work out reasonable flow chart as per customers' requirements to save space.

Hongyang Machinery Cetificates and Patents.

1 / International certification, National Certificate of equipment verification, and more than 40 invention patents are done in Hongyang Machinery .

2 / Verification Certificates of equipments: ISO9001:2015; CE Certificate , TUV

3 / National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Saso certificate of Saudi Arabia, etc.

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to Honyang Machinery site

● The meaning of visiting supplier, because seeing is believing, Honyang Machinery with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE HonGYANG MACHINERY HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will assembling all the machines and run parts testing for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF HonGYANG MACHINERY!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● We will arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

If you want to know more HonGYANG MACHINERY service , pls send us inquiry without hesitate !

Recommend Products