The Best Machines, The Best Service, The Best ValueAlpha CNC is in leading of Chinese CNC industrial for over a decade.By focusing on unbeatable customer service and high-quality control,Weve grown fr...

- YRS

The Best Machines, The Best Service, The Best ValueAlpha CNC is in leading of Chinese CNC industrial for over a decade.By focusing on unbeatable customer service and high-quality control,Weve grown fr...

| Min. Order / Reference FOB Price | |

|---|---|

| 10 Sets | US $59990.00/ Sets |

| Local Area: | Jinan, Shandong, China |

|---|---|

| R&D Capacity: | OEM, ODM, Other |

| Payment Terms: | LC, T/T, D/P, Paypal, Western Union |

| Brand: | Alpha |

|---|---|

| Application: | Laser Cutting |

| Condition: | New |

| Applicable Material: | Metal |

Product Description

ATF-3015-F fiber laser cutting machine is Alpha‘s new design, which is designed by European designers. It is more in line with modern aesthetics. The main parts of the machine are all world famous brand, such as the Japan Fuji drive motor, the German Vastun square rail and helical rack, the Taiwan TBI ballscrew on Z axis, Switzerland Raytools laser head, France Schneider and American Honeywell Low Voltage Electric parts. It has many uses and can save the space of more than 50%, which effectively improve productivityApplication Material

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting like stainless steel sheet, mild steel plate, carbon steel sheet, alloy steel plate, spring steel sheet, iron plate, galvanized iron, galvanized sheet, aluminum plate, copper sheet, brass sheet, bronze plate, gold plate, silver plate, titanium plate, metal sheet, metal plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture billboard, advertising, signs, signage, metal letters, LED letters, kitchen ware, advertising letters, sheet metal processing, metals components and parts, ironware, chassis, racks & cabinets processing, metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, glasses frame, electronic parts, nameplates, refrigeration machinery, agricultural machinery, food machinery, kitchen stainless steel countertops, aerospace, railroad locomotive, auto parts manufacturing, car body processing, medical equipment, smart home, home appliances, kitchen equipment, fitness equipment, machinery manufacturing, sheet metal processing. etc.

Working Area | 3000*1500mm |

X axis working area | 3,000mm |

Y axis working area | 1,500mm |

Laser Power | 2000W/3000W for option |

Positioning accuracy | ±0.03mm |

Repeatability positioning accuracy | ±0.02mm |

XY Axis Maximum Acceleration | 1g |

XY Axis Max. speed | 80m/min |

Working Table | Serrate working platform |

XY Axis Transmission system | German helical rack and pinion |

Z axis Transmission system | Taiwan TBI ballscrew |

Cooling System | Industry water chiller |

Power Supply Rated Voltage | 3-phase 380V/50Hz or Custom made |

Machine Weight | 4,000KG |

Dimension | 2250*4200*2100mm |

Detailed Images

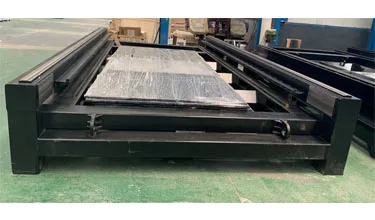

Heavy duty steel welded machine frame

Our machine frame is heavy duty, steel welded and we have the aging vibration process, annealed process. So the machine will not get deformed for long time use.

Here is the process of how we make our machine frame:

Using the thick steel pipe to weld the machine frame→ Annealing process→ Rough machining→ Vibratory Stress Relief → Fine machining

Aerospace aluminum machine gantry beam

Aerospace aluminum was manufactured using aerospace standards and extruded using a 4,300 ton press. After the aging treatment, the hardness can reach T6, which is the strongest of all beams. The aviation aluminum has good toughness, light weight, corrosion resistance, oxidation resistance and low density, which can greatly improve the processing speed.

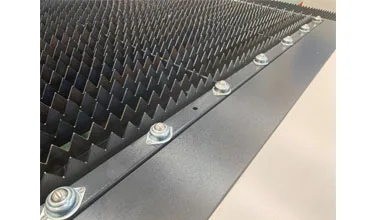

Protective Plates Shield for machine bed(more than 3kw)

For machines above 3kw, additional protecting plates are placed on the brackets of the bed to protect the bed from high-power laser cutting. When the the protecting plates shield is cut by the high power laser, it can be replaced at any time.

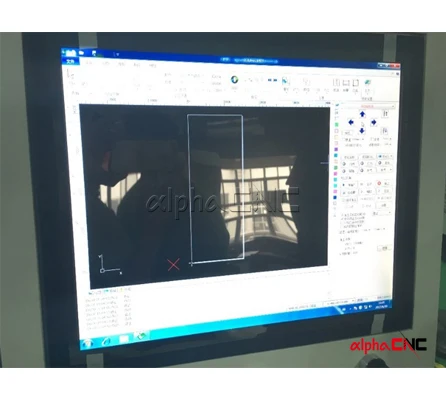

CypCut Controller

Functional possibility:

1.Supports three levels of perforation, segmentation or progressive combination

2.Support communication control of most mainstream lasers in the market

3.Supports basic processes such as flying cutting, leapfrog, compensation, threading, micro-connection, pre-perforation, film

cutting

4.Supports capacitor patrol edge, photoelectric, electric focusing, double table, automatic cutting tube cutting, power-off memory

and other advanced functions

5.Advanced technology such as cooling point, sharp corner cutting, release angle, etc.

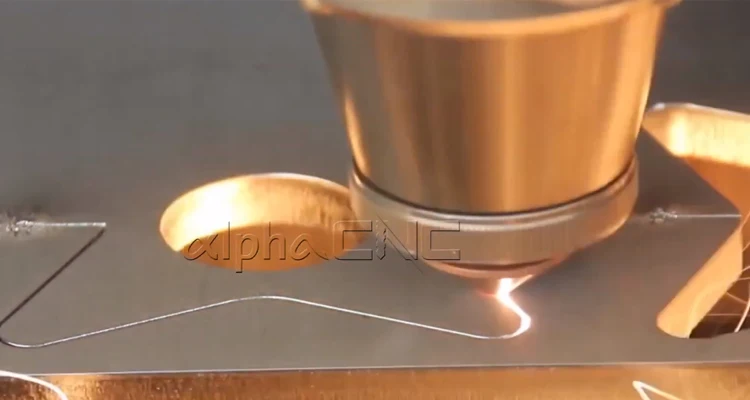

Switzerland Raytools laser head

Swiss RAYTOOLS introduces an autofocus fiber cutting head. The product has a built-in motor drive unit that automatically changes

the position by driving the focusing mirror through a linear mechanism. The user can continuously adjust the focus through the program to complete the rapid perforation of the thick plate and automatically cut the plates of different thicknesses and materials. The product is equipped with a composite lens unit to integrate the beam, and the optical and water-cooled design is

optimized so that the laser head can work stably for a long time at high power.

Raycus Laser Generator

The multi-module continuous fiber laser series developed by Raycus Laser covers products between 1500W and 20kW. It has high electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, high reliability, long

life and maintenance-free operation. And so on, can be widely used in welding, precision cutting, cladding, surface treatment, 3D printing and other fields. Its fiber output features make it easier to integrate with robots into flexible manufacturing equipment to meet the needs of 3D machining.

Control Cabinet

All the electrical components are housed and wired in a doubled-doored electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet

Automatic lubrication system

The function of the automatic oil pump is mainly to perform regular quantitative oiling on the easily wearable guide rail, ballscrew and the rack gear. It is by the digital controller to control the lubrication pump working cycle; lubrication time and intermittent time.

Big Independ Control Cabinet

Control panels, drivers, and other low voltage components are installed in the control cabinet. Larger space helps to place and

dissipate electrical components. It can prevent interference to the greatest extent.

Japan Yaskawa servo motor

Japan Yaskawa servo motor is top brand in all over the world. Yaskawa servo motor is installed on XYZ axis. The big powerful servo motor on Y axis, makes the machine cutting at high speed, the Max. speed can be 80m/min. Moreover, the Yaskawa servo motor is famous for the high precision and stable performance.

Taiwan PMI or Hiwin Guide Rail

Optimized lubrication channel design minimizes lubricant consumption Lubricated interface on all sides for easy maintenance

Integrated induction, wear-free measuring system with a maximum measuring length of 4m and a resolution of less than 1μm PMI guide system allows you to move the heaviest loads with minimal force while ensuring the design rigidity and precision required by high performance machine and robot users. A variety of precision roller guide systems are available.

The machine comes with the feeding roll. The feeding roll will help the worker feed the material easily.

XY Axis Taiwan Hiwin/ PMI Square Rail &Taiwan or German Rack Transmission system

The machine adopts German Rexroth square rail, which is more durable. And the use of high quality helical rack pinion, makes

ithigh precision. The rack and pinion on XY axis is from Taiwan YYC. The high hardness of the material makes the rack more wear resistant.

Sample

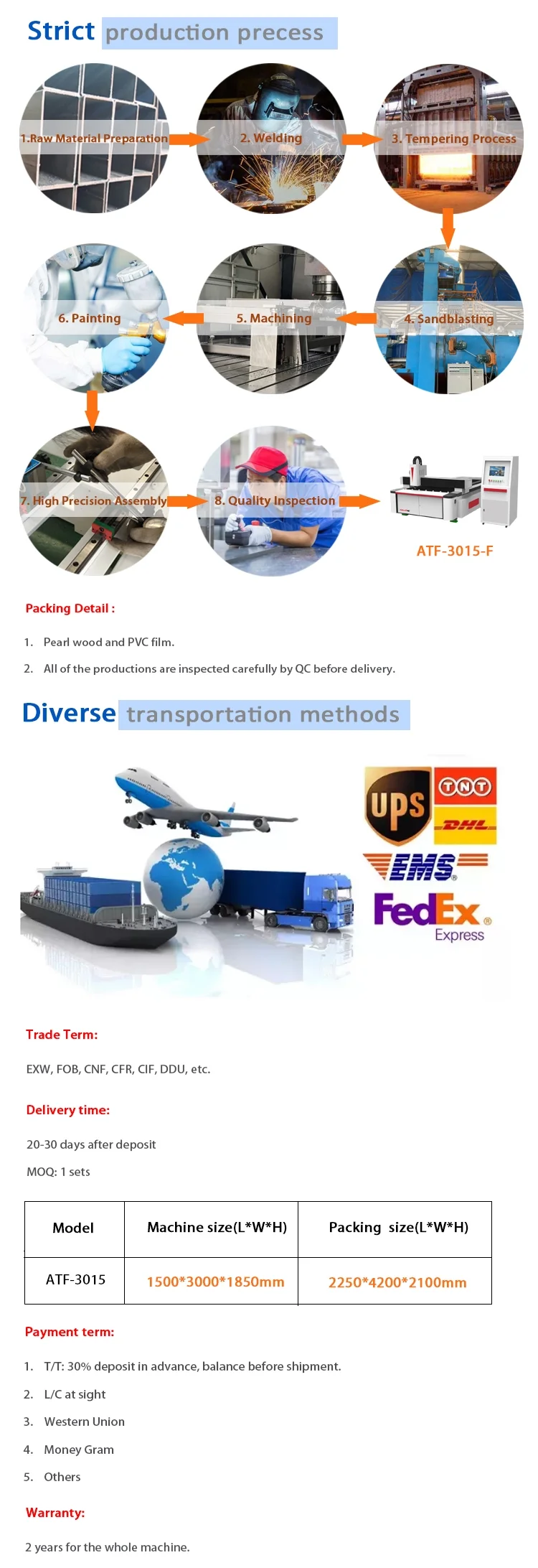

Packing & Delivery

Certifications

After Sales Service

1. The warranty period is 2 years for the machine.

2. We will provide the consumable parts at an agency price when you need replacement.

3. Main parts shall be changed free of charge if there is any problem within the warranty period.

4. Software is on update for free whole life.

5. Free training at Alpha factory.

6. 24 hours technical support on line(Call, Email, Teamviewer, Whatsapp, Skype, Wechat, QQ, etc.)

7. On-site local training is available.

about Us

More Pictures