Henan Doing Machinery Equipment Co., Ltd. has been dedicated to the research and development of large and medium-sized renewable energy environmental protection equipment and a variety of waste recycl...

- YRS

Henan Doing Machinery Equipment Co., Ltd. has been dedicated to the research and development of large and medium-sized renewable energy environmental protection equipment and a variety of waste recycl...

| Min. Order / Reference FOB Price | |

|---|---|

| 1 Set | US $98000.00/ Set |

| Local Area: | Zhengzhou, Henan, China |

|---|---|

| R&D Capacity: | OEM, ODM, Other |

| Payment Terms: | LC, T/T, D/P, Paypal, Western Union |

| Brand: | DOING |

|---|---|

| Place of Origin: | Henan, China |

| Brand Name: | DOING |

| Machine Type: | waste aluminum plastic composite panel recycling machine |

| Pollution free waste aluminum plastic composite panel recycling machine |

Product Description

| Product Introduction of waste aluminum plastic composite panel recycling machine |

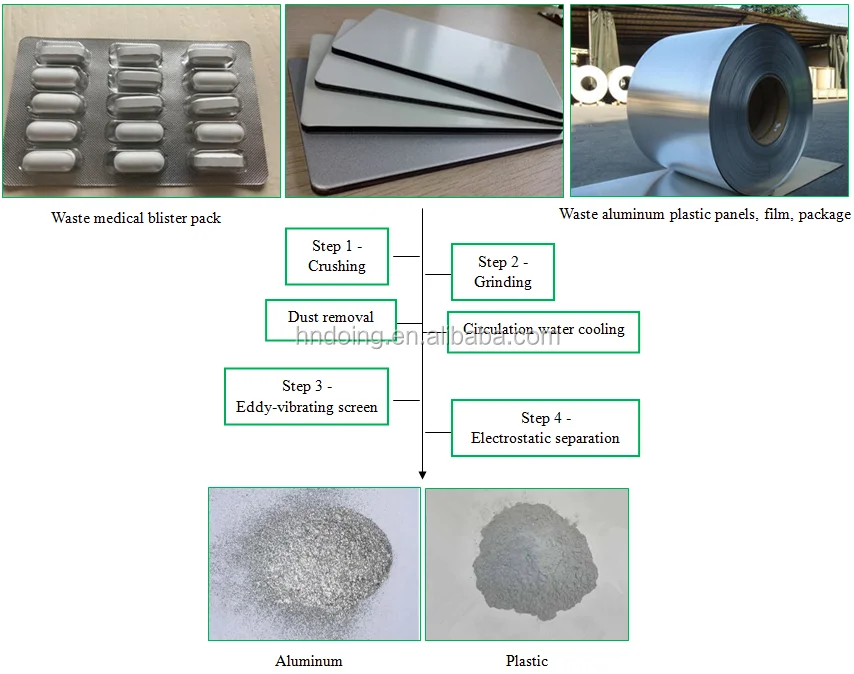

Waste aluminum plastic composite panel recycling machine is used to separate and recycle aluminum and plastic from scrap aluminum plastic composite materials through a crushing, grinding, eddy-vibrating screen and electrostatic separation process. The process adopt totally dry type and physical separation method, no water, no fire, no chemical, completely environmental friendly. The aluminum plastic separation machine is applicable to process all kinds of aluminum-plastic leftover materials and waste scraps from pharmaceutical factory, aluminum-plastic panel factory, food and beverage factory and other aluminum foil packaging industry. The separation rate of aluminum and plastic could reach to 99%, which the recycled aluminum could be directly used for smelting aluminum ingots, or directly used in aluminum powder factory, fireworks plant and aluminum plant, while the separated plastic can be used to make plastic sheets, tubes, packages and water pipes. This makes the aluminum plastic separation recycling business has a big potential market. In addition, the aluminum plastic separation recycling machine has the advantages of fully automatic PLC control system, easy to operate; equipped with circulating water cooling system to make sure the high separation rate during grinding process; operated with high efficiency vacuum loading and dedusting system

| Working Process of waste aluminum plastic composite panel recycling machine |

Any kinds of aluminum plastic composite materials, like waste medical blister pack, aluminum plastic film, package, panel, sheet, tubes, etc, could be processed by this machine. Firstly through crusher to get the aluminum plastic materials into small particles, then go to grinder for further grinding to make aluminum and plastic separated apart. To be noticed, the grinding system should have circulation water cooling system to make sure no plastic melted during grinding process, thus cause melting or coking of the materials. After grining, materials go through eddy-crurrent screen to separate big particles which may still have aluminum and plastic stick together, then go back to grinder for re-grinding. The small particles will directly go to electrostatic separator for separation, thus to get pure aluminum and plastic.

| Main Advantages of waste aluminum plastic composite panel recycling machine |

Fully automatic PLC control system

1.The whole process of our plastic and aluminum recycling machine is under PLC control, fully automatic, easy to operate.

High voltage electrostatic separation

2.The plastic and aluminum recycling process adopts electrostatic separation technology, dry type physical separation method, no fire, no water, no chemical, totally clean and pollution-free.

Water cooling for high separation rate

3.The crushing and grinding process working with water cooling system, which avoid high temperature generated to make plastic melted and stick on aluminum, ensure the high separation rate.

High efficiency pulse dust collector

4.The plastic and aluminum recycling machine is equipped with pulse dust collector, which could make sure a clean working environment without dust fly around.

Packaging & Shipping

| Packaging & Shipping of waste aluminum plastic composite panel recycling machine |

Our Services

|